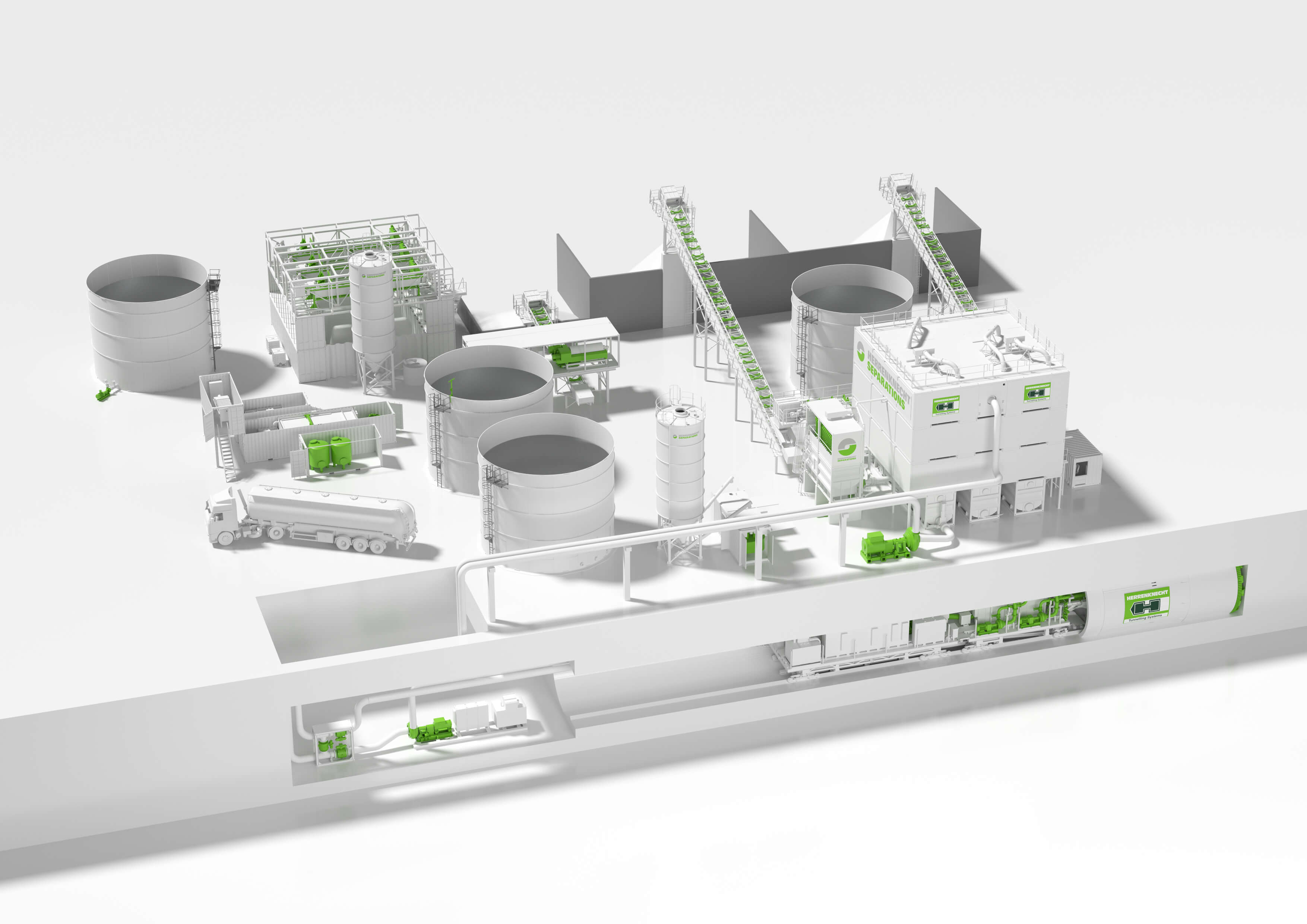

Herrenknecht Separation Plants are optimally tailored to the requirements and challenges of our international customers projects. During tunnelling operations, the plants continuously separate the loaded suspension (also called slurry) from the solid particles in the slurry circuit. State-of-the-art screening technology and hydrocyclones, in a powerful interplay of high G-forces and low cut points, deliver landfill or re-usable solids with low water content. The reduced muck weight also reduces disposal and recycling costs. Over time, fine particles remaining in the suspension that cannot be separated have a negative effect on important process parameters such as advance speed and daily advance rate and leads to higher wear and tear of the components. Additional equipment for the separation of fines is therefore required to prevent thickening of the slurry and to ensure efficient tunnelling over the long term. Filter presses, centrifuges or density regulation separate fines effectively. An adaptable separation plant forms the basis for successful implementation for the successful application for solid-liquid separation, for example, for the use of slurry-supported tunnelling machines such as AVN machines, Mixshields, Variable Density Machines or Vertical Shaft Sinking Machines (VSM). Separation plants optimally matched to the project’s requirements enable an ideal interaction between jacking and separation and thus maximize the jacking performance and ensure smooth operations.

Separation Plants

Separation plants separate solid particles from suspensions in a variety of ways. Multi-stage, high-performance screening machines and hydrocyclones are used for this purpose. Efficient, reliable components specially adapted to the requirements guarantee optimum results in the entire separation process. The modular container design minimizes transport costs and installation times and ensures easy handling.

Fine Treatment

The Density Regulation System, centrifuges and filter presses are used for fine treatment of solids-laden suspensions. This multi-stage process reduces disposal costs and significantly improves the quality of the medium to be cleaned for possible reuse. Like all Herrenknecht Separation systems, the fine treatment technologies are available in modular container form.

Water Treatment Plants

Wastewater occurring at tunnel jobsites, such as drainage, filtration or washing water as well as rainwater, must be treated before it can be discharged into the natural environment or returned to the cycle. To meet the requirements depending on legislation and project constraints, Herrenknecht Separations has developed a modular, containerized and pre-assembled water treatment plant. The system is easy to transport, install, operate and expandable if required/necessary.

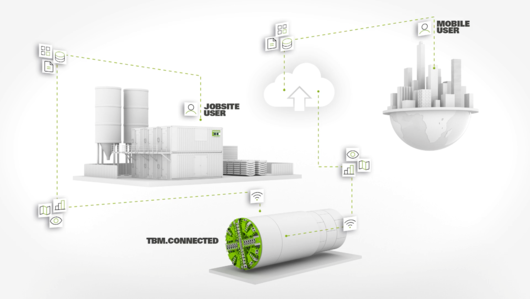

Service

Our project partnership doesn't end with delivery and commissioning. We support our customers worldwide in all project phases. With professional and fast on-site service, timely supply of spare parts and our profound expertise: a smooth process is a prerequisite for best performance in your project.

With our reconditioning and refurbishment service, we offer you the possibility of having the plant professionally reconditioned after successful use by our experts in accordance with manufacturer specifications. This means proven components can be reused for subsequent projects. Our comprehensive warranty on all reconditioned products ensures uncompromising performance and safety.

As an alternative to purchase, Herrenknecht Separations also offers rental options as well as buyback options for selected components. This way, you remain flexible and your investment sums remain low. We will be happy to provide you with information about our current available offers in the rental pool.